Family Sites

Green Solutions

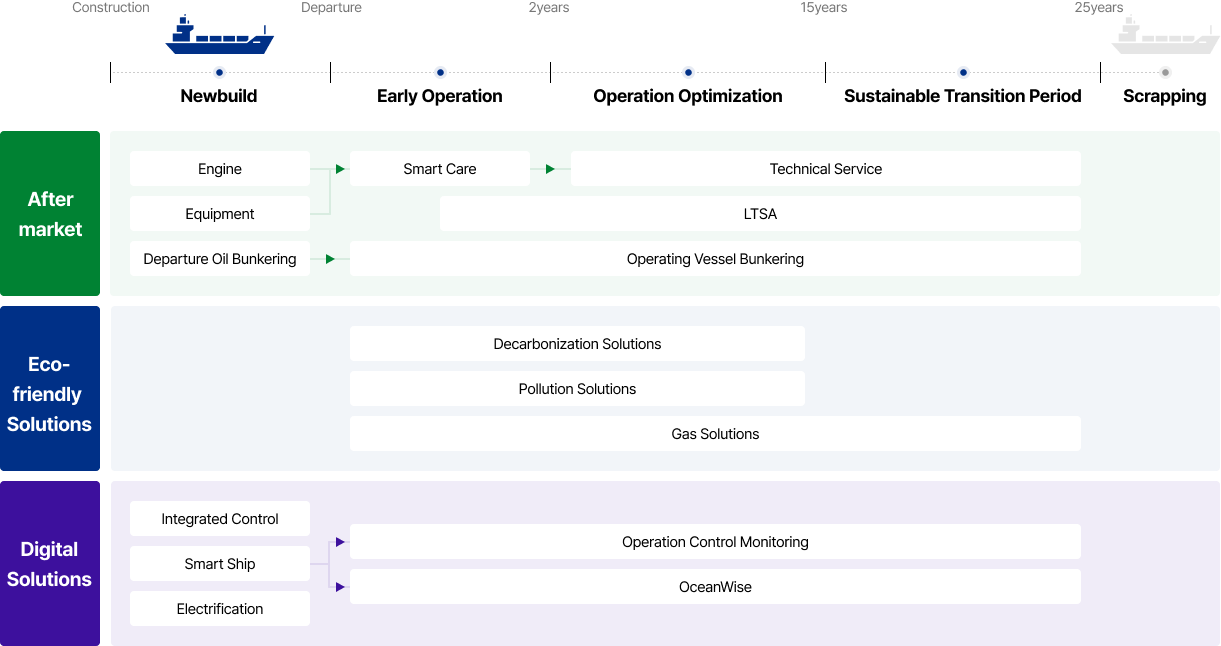

Approximately 1 billion tons of CO₂ are emitted annually from global maritime transport. HD Hyundai Marine Solution provides a range of decarbonization retrofit solutions for shipping companies and charterers in line with global decarbonization trends, including RE100 and Net-Zero.

Decarbonization Solutions

-

Dual-Fuel Engine Retrofit (DF Engine)

A dual-fuel engine retrofit is a technology that converts existing single-fuel engines into dual-fuel engines capable of using two fuels. This enables a response to green fuel regulations adopted at the IMO and MEPC 83 meetings and allows the use of next-generation green fuels such as LNG, methanol, ammonia, and even hydrogen.

-

1. Harmful Substance Emission Reduction

Significantly reduce harmful substance emissions—such as SOx, NOx, and CO₂—from exhaust gases, thereby improving environmental regulatory compliance.

-

2. Operational Flexibility

When a green alternative fuel supply is difficult, conversion/operation with existing fuel is possible, providing high operational flexibility.

-

1. Harmful Substance Emission Reduction

-

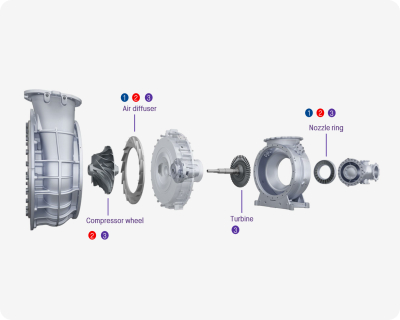

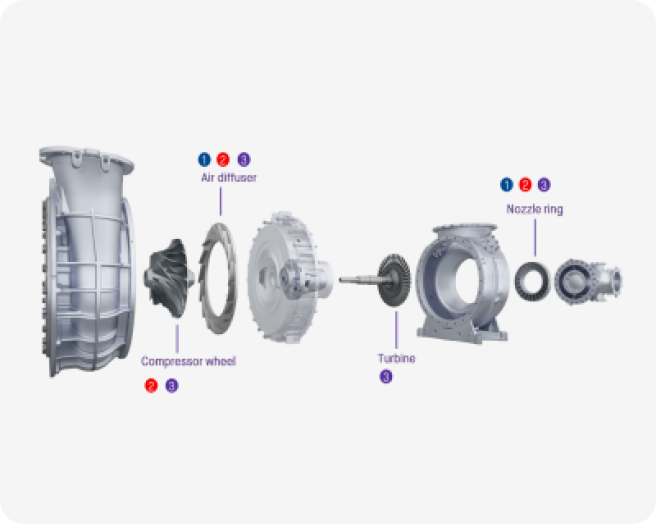

Engine Part-Load Optimization (EPLO)

Engine Part-Load Optimization (EPLO) is a technology that retrofits engines and turbochargers to optimize for actual operating speeds. This enables reduced fuel consumption, improved environmental performance, and enhanced overall vessel operational efficiency.

-

1. Fuel Reduction and Environmental Performance Improvement

Expect up to 6g/kWh in fuel efficiency improvements, along with reduced carbon emissions. Suppress carbonization deposits to extend engine life and reduce maintenance costs.

-

2. Operational Efficiency Enhancement

Enable high combustion efficiency and operational efficiency improvements through turbocharger retrofitting optimized for actual vessel operating speeds.

-

1. Fuel Reduction and Environmental Performance Improvement

-

Alternative Maritime Power (AMP)

Alternative Maritime Power (AMP) is a technology that meets a vessel's electrical demand by supplying power from shore while the vessel's engine is stopped during berthing. This enables improvements in air quality near ports and an effective response to environmental regulations.

-

1. Zero Emissions and Air Quality Improvement

By stopping engine operation during berthing and using shore power, emissions of SOx, NOx, CO₂, and particulate matter are eliminated, reducing air and noise pollution near ports.

-

2. Enhanced Environmental Regulation Response

With AMP installation and use becoming mandatory at major ports, including IMO, North America, Europe, and China, this enables an effective response to international and regional environmental regulations.

-

1. Zero Emissions and Air Quality Improvement

-

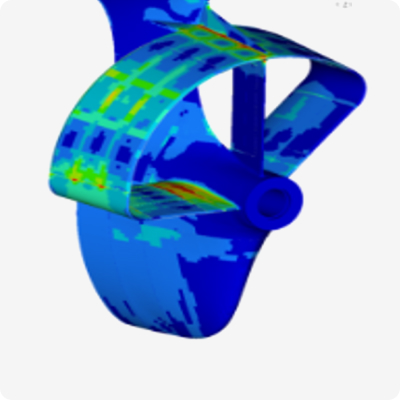

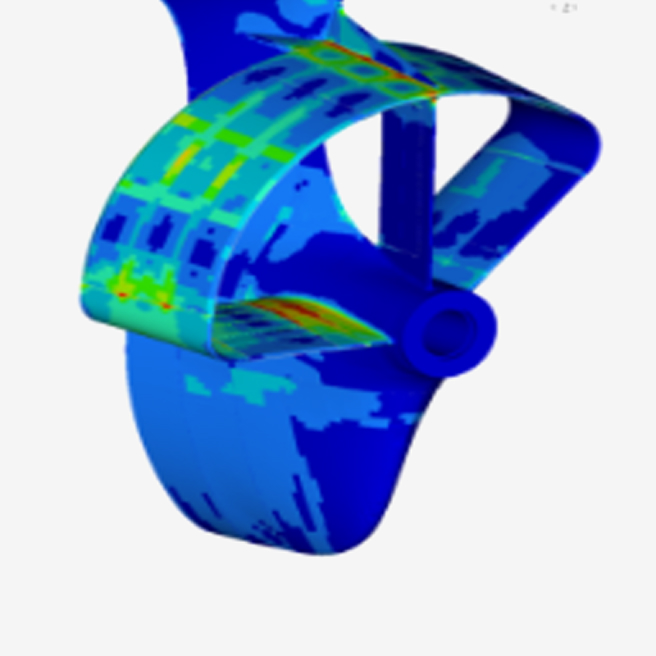

Propeller Re-design

Propeller redesign is a technology that maximizes propulsion efficiency and operational performance by optimizing propeller shape, size, blade count, pitch, material, and other parameters based on actual vessel operating conditions.

-

1. Propulsion Efficiency and Fuel Reduction

Reduce energy loss and improve fuel efficiency through a design optimized for operating conditions, reducing operational costs.

-

2. Noise and Vibration Reduction

Reduce cavitation by improving flow conditions and minimizing noise and vibration impacts on vessel structures and crew.

-

1. Propulsion Efficiency and Fuel Reduction

-

Bulbous Bow Optimization

Bulbous bow optimization is a technology that enhances operational efficiency by minimizing wave-making resistance through redesigning the bulbous bow to match actual vessel operating conditions.

-

1. Drag Reduction and Propulsion Efficiency Enhancement

Reduce overall drag by decreasing wave resistance and secure more thrust with the same engine output, increasing propulsion efficiency.

-

2. Fuel Reduction Effect

Energy required for propulsion decreases due to drag reduction, reducing fuel consumption.

-

1. Drag Reduction and Propulsion Efficiency Enhancement

-

Air Lubrication System (ALS)

An Air Lubrication System (ALS) is a technology that reduces frictional resistance by injecting air at the vessel's bottom to form an air layer between the hull and seawater.

-

1. Fuel Reduction and Greenhouse Gas Reduction

Reducing friction resistance decreases fuel consumption and emissions of CO₂, NOx, and SOx, making it effective for environmental regulatory response.

-

2. Operating Cost Reduction

Enable a total reduction in vessel operating costs through fuel savings.

-

1. Fuel Reduction and Greenhouse Gas Reduction

-

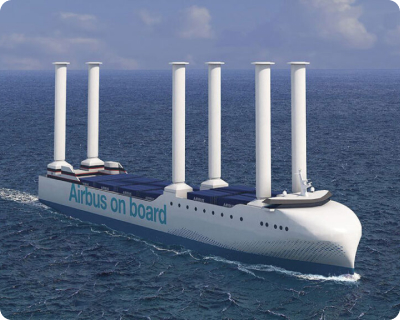

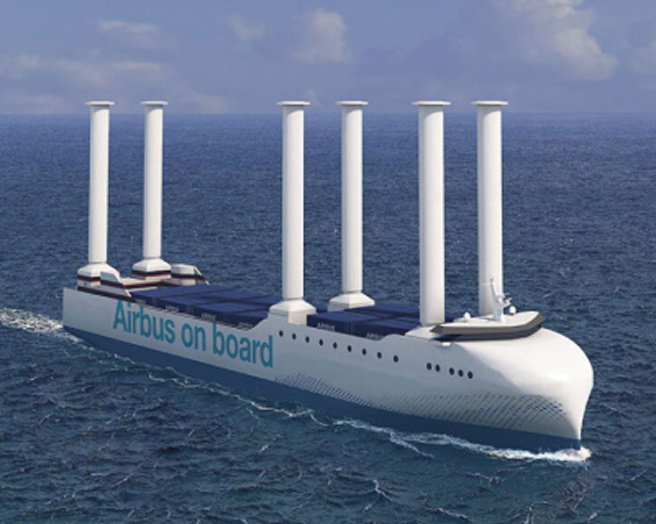

Wind Assisted Propulsion System (WAPS)

Wind Assisted Propulsion System (WAPS) is a system that assists vessel propulsion using wind power, reducing fuel consumption and carbon emissions.

-

1. Fuel Reduction and Greenhouse Gas Reduction

Utilize wind power as auxiliary power to reduce engine load and simultaneously decrease fuel consumption and greenhouse gas emissions.

-

2. Operating Cost Reduction

Enable a total reduction in vessel operating costs through fuel savings.

-

3. Operational Efficiency Enhancement Through Incentive Acquisition

Acquire incentives in accordance with Fuel EU Maritime regulations to enhance vessel operational efficiency.

-

1. Fuel Reduction and Greenhouse Gas Reduction

-

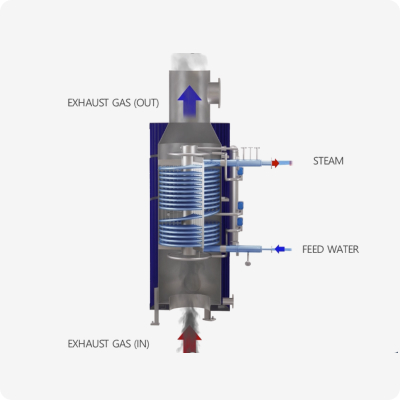

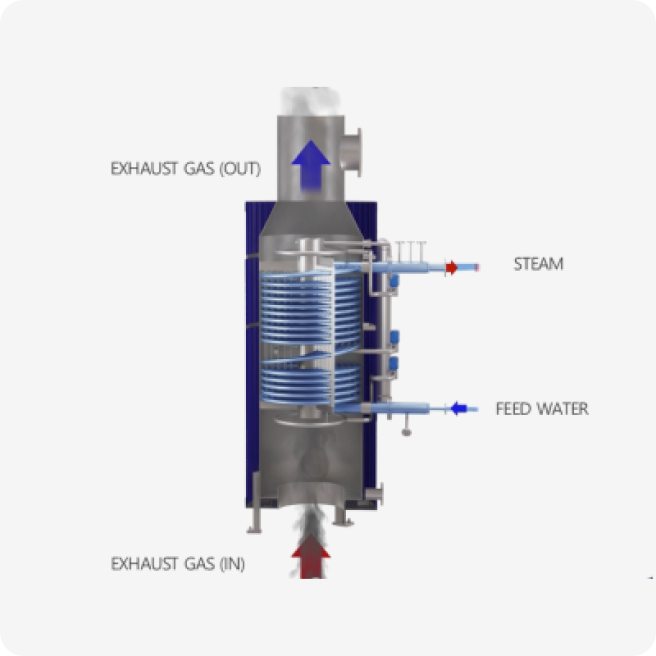

Exhaust Gas Boiler

An Exhaust Gas Boiler is a technology that heats water using high-temperature exhaust gases generated from vessel engines. Recycling exhaust gases reduces fuel consumption compared to conventional boilers and maximizes vessel energy efficiency.

-

1. Fuel Reduction and Operating Cost Reduction

Reduce fuel consumption by utilizing exhaust gas heat instead of conventional boilers, thereby reducing operating costs.

-

1. Fuel Reduction and Operating Cost Reduction

-

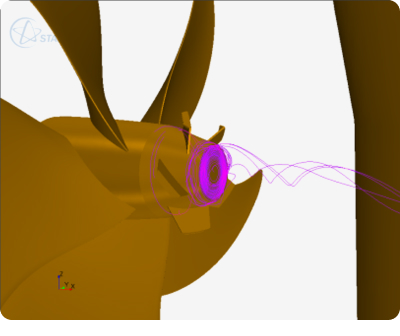

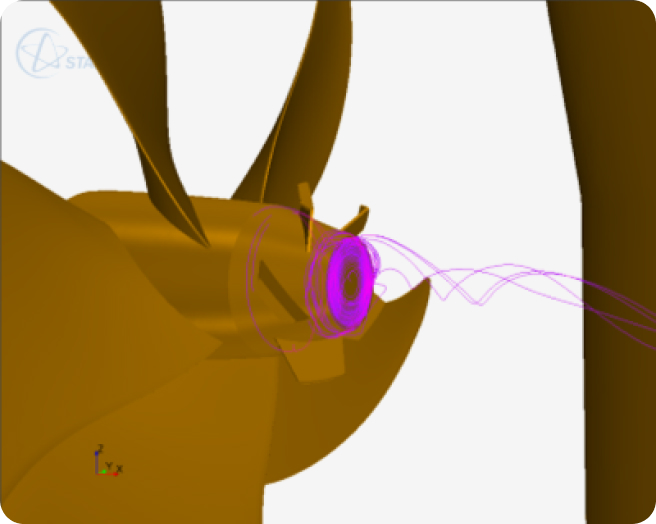

Propeller Hub Cap (Hi-Fin)

A propeller hub cap (Hi-Fin) is a technology that enhances vessel propulsion efficiency by attaching small fin devices to the propeller center (hub/boss cap) to control vortices generated behind the propeller.

-

1. Propulsion Efficiency Enhancement and Low-Speed Operation Optimization

Improve propulsion efficiency by reducing vortices, enabling reduced fuel consumption. Demonstrates greater efficiency improvements, especially at low speeds.

-

1. Propulsion Efficiency Enhancement and Low-Speed Operation Optimization

-

Pre-Swirl Duct (Hi-PSD)

A pre-swirl duct (Hi-PSD) is a structure installed in front of the propeller that controls fluid flow from the hull to induce rotational motion in advance. It is equipment that enhances propeller efficiency and reduces fuel consumption by optimizing the velocity distribution of water reaching the propeller.

-

1. Propulsion Efficiency and Fuel Reduction

Improve propulsion efficiency by controlling fluid flow in advance and reducing fuel consumption to lower operational costs.

-

2. Resistance Reduction and Vibration Mitigation

Mitigate flow interference between hull and propeller and reduce vibration and noise by equalizing velocity distribution.

-

1. Propulsion Efficiency and Fuel Reduction

-

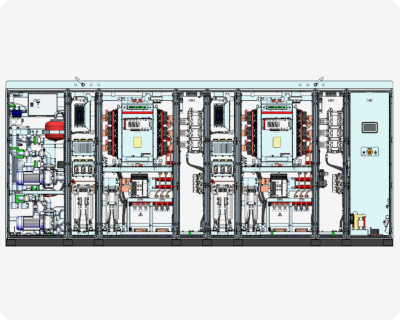

Variable Frequency Drive (VFD)

A Variable Frequency Drive (VFD) is a technology that controls the speed and torque of AC motors by adjusting the frequency of the power supply (Hz).

-

1. Fuel Reduction and Operating Cost Reduction

Reduce fuel costs and operating costs by decreasing energy consumption through enhanced motor operation efficiency.

-

2. Equipment Protection and Precise Control

Prevent equipment overload and damage by precisely controlling motor speed and torque, and improve system performance and reliability.

-

1. Fuel Reduction and Operating Cost Reduction

Have Questions?

We provide prompt, accurate answers to online inquiries.

-

Go to

Customer Materials Download

Brochures/Catalogs/Manuals/Certificates You can download materials for customers.

-

Go to

FAQ Frequently Asked Questions

You can check the frequently asked questions and customer answers.

-

Go to

1:1 Inquiry

When you ask questions according to inquiry type, our staff will respond quickly and kindly.

Now Loading.

Please wait a moment.

HD현대마린솔루션의 모바일 웹은 세로화면에 최적화되어 있습니다.