Family Sites

Green Solutions

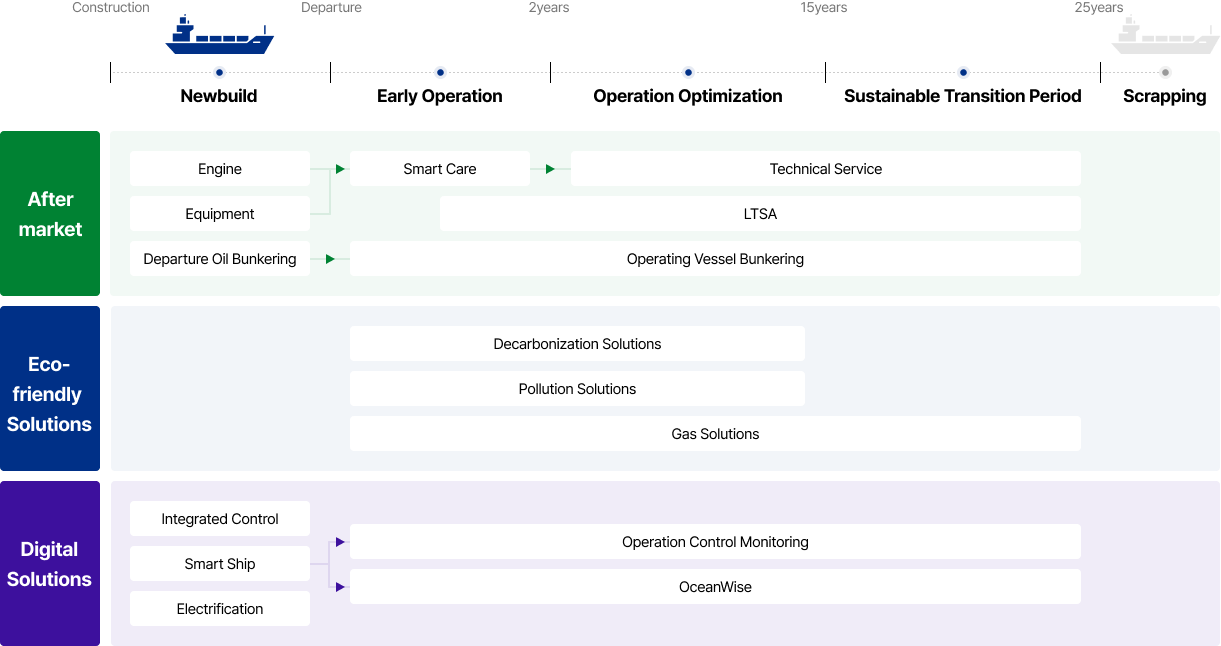

HD Hyundai Marine Solution provides various gas-based solutions to support vessel green transitions in response to increasingly stringent environmental regulations.

Gas Solutions

-

Floating Storage Regasification Unit (FSRU / FSU)

A Floating Storage Regasification Unit (FSRU) / Floating Storage Unit (FSU) is a floating vessel-type LNG storage and regasification facility that stores LNG in its liquid state, then regasifies it and supplies it as natural gas to land and sea. By converting existing LNG carriers into FSRUs/FSUs, they can serve as mobile LNG terminals capable of importing and processing LNG without building large-scale land facilities.

-

1. Rapid Installation and Operation

Converting existing LNG carriers to FSRU/FSU can be completed more quickly than new land-based LNG terminal construction, enabling commercial operation to begin sooner.

-

2. Economical and Flexible Utilization

Economical with lower initial investment costs compared to new land-based LNG terminal construction. FSRU/FSU locations can be moved in response to changes in natural gas demand, enabling a flexible response to regional energy demand.

-

1. Rapid Installation and Operation

-

LNG Reliquefaction Facility

Reliquefaction equipment is a device that cools and liquefies LNG (liquefied natural gas) back into a liquid. LNG is maintained as a liquid at cryogenic temperatures for storage and transport, maximizing storage and transport efficiency through reliquefaction.

-

1. Maximized Storage and Transport Efficiency

The liquid state has a much smaller volume than the gas state, allowing more LNG to be stored in the same space. Reduced volume increases transport efficiency and reduces costs.

-

2. Safety Assurance

Natural gas in the gaseous state can be dangerous due to its high volume and pressure, but liquid-state management enables safer handling.

-

3. BOG (Boil-Off Gas) Management

Minimize cargo loss by converting gas (BOG, Boil-Off Gas) generated from partial vaporization of liquid natural gas back to liquid LNG through reliquefaction equipment. Additionally, effectively respond to environmental regulations by minimizing BOG combustion to reduce CO₂, NOₓ, and CH₄ (methane slip) emissions.

-

1. Maximized Storage and Transport Efficiency

-

Large Engine Methane Slip Solution (iCER)

Large-engine methane slip solution (iCER, Intelligent Control by Exhaust Recycling) is a technology that reduces unburned methane emissions by recirculating dual-fuel engine exhaust gas back into the combustion chamber.

-

1. Greenhouse Gas Reduction and Fuel Savings

To address unburned methane emissions during low-load operation of dual-fuel engines, apply exhaust gas recirculation technology to reduce them by approximately 50%. Additionally, improve fuel efficiency through compression ratio enhancement to achieve an average fuel consumption reduction of 6~12 g/kWh.

-

1. Greenhouse Gas Reduction and Fuel Savings

-

Medium-Speed Engine Methane Slip Solution (MSS)

Medium-speed engine methane slip solution (MSS) is a technology that reduces methane (CH₄) emissions into the atmosphere from internal combustion engines (especially gas engines) or from boilers that do not achieve complete combustion.

-

1. Greenhouse Gas Reduction and Fuel Savings

Effectively reduce unburned methane emissions by applying technologies such as Cylinder Cut Off (CCO), Multi-Pilot Injection (MPI), combustion temperature optimization, and methane oxidation catalyst systems.

-

1. Greenhouse Gas Reduction and Fuel Savings

Have Questions?

We provide prompt, accurate answers to online inquiries.

-

Go to

Customer Materials Download

Brochures/Catalogs/Manuals/Certificates You can download materials for customers.

-

Go to

FAQ Frequently Asked Questions

You can check the frequently asked questions and customer answers.

-

Go to

1:1 Inquiry

When you ask questions according to inquiry type, our staff will respond quickly and kindly.

Now Loading.

Please wait a moment.

HD현대마린솔루션의 모바일 웹은 세로화면에 최적화되어 있습니다.