Family Sites

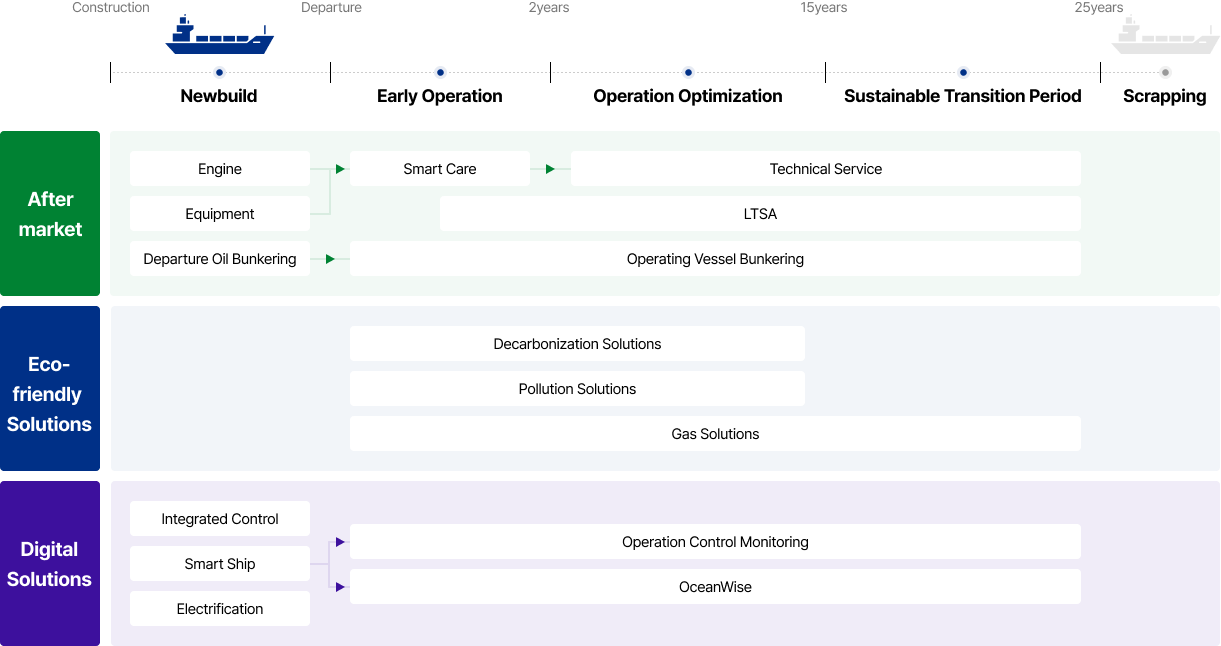

AFTER MARKET

Based on extensive experience and a global network, we provide a one-stop supply of major mechanical and electrical components, consumables, and engineering services, supporting customer maintenance schedules safely and efficiently. We proactively identify customer needs by analyzing new-vessel status and shipowner fleet-operational data, and achieve optimal lead times by securing inventory in advance.

Equipment

Gas Handling

-

FGSS

FGSS (Fuel Gas Supply System) is an integrated system responsible for fuel storage and gas supply, pressure regulation, and safety management for the use of liquefied gas, such as LNG, as fuel on vessels.

-

1. Environmentally Friendly

Highly effective in responding to international environmental regulations by dramatically reducing harmful emissions such as nitrogen oxides (NOx) and carbon dioxide (CO₂) through LNG fuel use.

-

2. Fuel Cost Reduction

Excellent economic efficiency with significant long-term fuel cost reduction as LNG has a lower unit price and higher thermal efficiency compared to conventional bunker oil.

-

3. International Standards Compliance

Smooth approval procedures from classification societies and regulatory authorities by satisfying IGF Code and other international safety regulations and environmental certification requirements.

-

1. Environmentally Friendly

-

LFSS

LFSS (Low-flashpoint Fuel Supply System) is an integrated system for safely supplying low-flashpoint fuels such as methanol, LPG, and ammonia to engines on vessels. It is a core equipment for next-generation green vessels, encompassing fuel storage, pumping, pressure and temperature control, and safety management.

-

1. Diverse Fuel Applicability

Feasible to process various low-flashpoint fuels, including methanol, LPG, and ammonia, enabling a flexible response to green fuel transitions. Applicable to both new vessel construction and existing vessel retrofits.

-

2. Operational Economy

Reduce energy consumption with a single-pump design and optimized control. Highly efficient and economical for long-term operation.

-

3. Safety and Regulatory Compliance

Designed to meet IGF Code and international safety regulations. Controls pressure and temperature, considering low-flashpoint fuel characteristics. Ensures operational stability with dual safety devices and leak detection systems.

-

1. Diverse Fuel Applicability

-

CHS

CHS (Cargo Handling System) is an integrated system essential for safely and efficiently loading, storing, transferring, and unloading cargo on vessels, particularly tankers such as VLGC, LNGC, and chemical tankers. This system consists of cargo pumps, valves, pipelines, pressure and temperature control devices, monitoring systems, and safety systems, ensuring both operational efficiency and vessel safety.

-

1. Efficient Cargo Management

Stably manages cargo throughout loading, storage, and unloading processes. Enhances work efficiency and minimizes labor burden through automation and remote control functions.

-

2. Economic Efficiency and Operational Optimization

Designed to minimize energy consumption during the cargo transfer process. Enables rapid unloading and loading, shortening port stay time and optimizing operation schedules.

-

3. Safety and Regulatory Compliance

Complies with IMO and international safety regulations for hazardous cargo transport. Ensures transport safety by preventing overpressure and temperature anomalies, detecting leaks, and applying emergency shut-off devices.

-

1. Efficient Cargo Management

Have Questions?

We provide prompt, accurate answers to online inquiries.

-

Go to

Customer Materials Download

Brochures/Catalogs/Manuals/Certificates You can download materials for customers.

-

Go to

FAQ Frequently Asked Questions

You can check the frequently asked questions and customer answers.

-

Go to

1:1 Inquiry

When you ask questions according to inquiry type, our staff will respond quickly and kindly.

Now Loading.

Please wait a moment.

HD현대마린솔루션의 모바일 웹은 세로화면에 최적화되어 있습니다.